Fabricated Flanges

Benchmark has supplied and fabricated a wide variety of piping products in support of the Oil & Gas Industry, LNG Plant Construction, Marine Services and Pulp / Paper Plants.

The variations of assemblies we have deployed are enormous, however typically a piping assemble consists of the following basic components:

- Piping

- Flanges

- Valves

- Fittings

- Stud Bolts

- Gaskets

- Isolation Kits

- and Pipe Spools AKA Flanged Spools

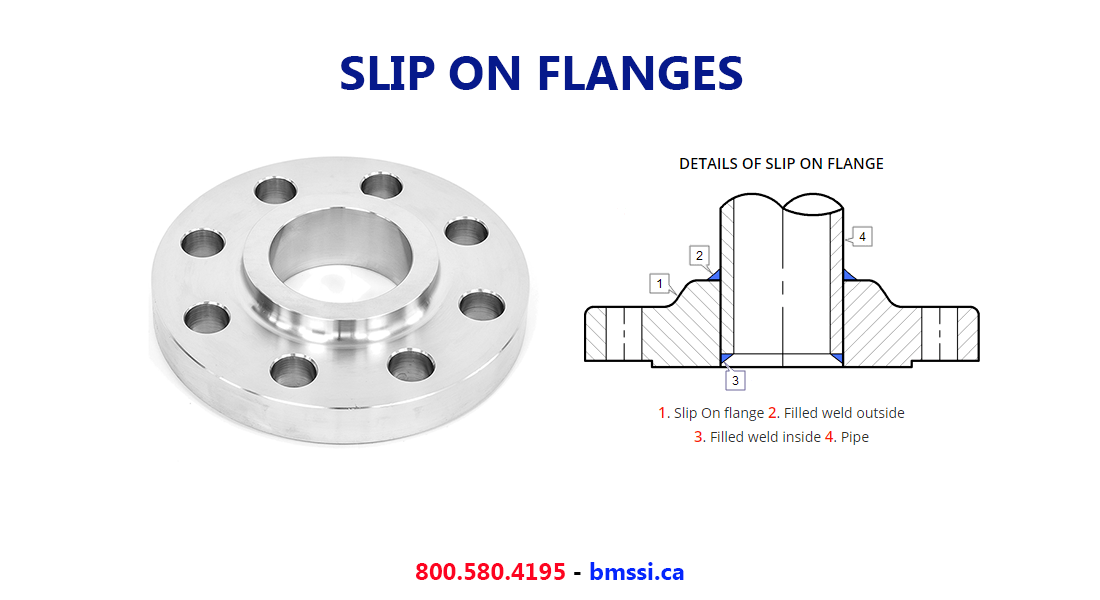

Slip on Flange is essentially a ring that is placed over the pipe end, with the flange face extending from the end of the pipe by enough distance to apply a weld bead on the inside diameter.

The OD of slip on flange is also welded on the back side of the flange. Slip on flanges have a lower material cost than weld neck flange and are more easily aligned.

Slip on flange may also be used a lap joint flanges if Type B or Type C stub ends are used.

The calculated strength from a Slip On flange under internal pressure is of the order of two-thirds that of Welding Neck flanges, and their life under fatigue is about one-third that of the latter.

The connection with the pipe is done with 2 fillet welds, as well at the outside as also at the inside of the flange.

The X measure on the image, are approximately:

Wall thickness of pipe + 3 mm.

This space is necessary, to do not damage the flange face, during the welding process.

A disadvantage of the flange is, that principle always firstly a pipe must be welded and then just a fitting. A combination of flange and elbow or flange and tee is not possible, because named fittings have not a straight end, that complete slid in the Slip On flange.

Please contact us today for more information about our wide range of Piping Products and Fabricated Piping Products. If you don’t see the type of gasket you need here? Not to worry! Benchmark has local stock on hundreds of types of Piping Products not listed and are updating our online inventory daily. What’s more if we don’t have it we will find someone who does and deliver to your site as fast as same day if possible.