Made in Canada

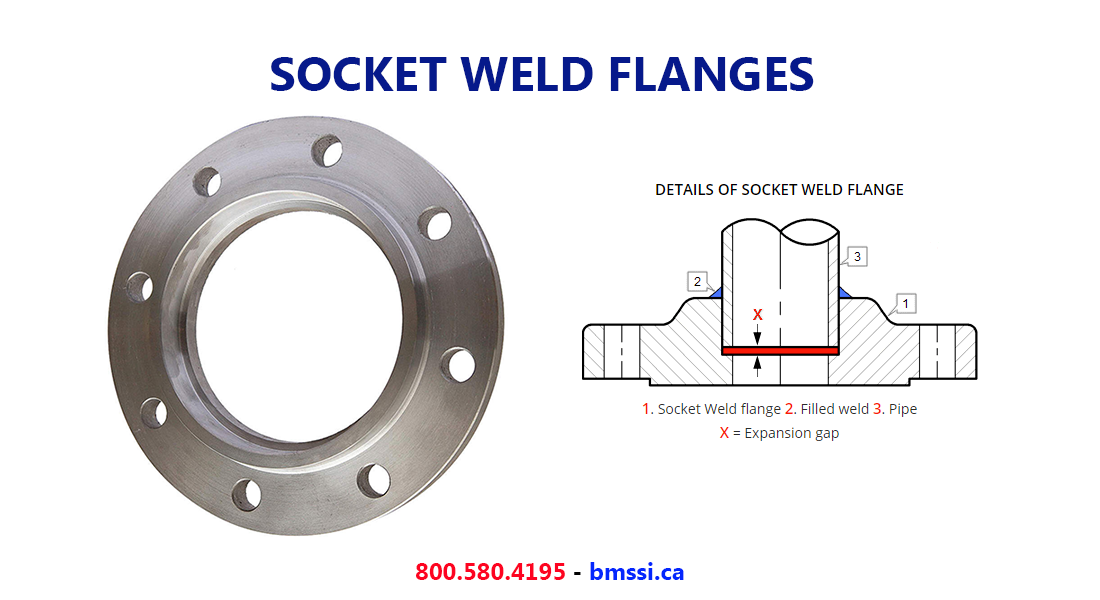

SW Flange (Socket Weld Flange) contain a shoulder on the inside of the flange that acts as a guide to set the depth at which the pipe is welded to the flange. They are fabricated by inserting the pipe end into the flange until it bottoms out against the shoulder, and then retracting the pipe 1/8 in before welding it in place. This practice was originally employed to reduce cracking due to thermal stresses in stainless steel superheaters, but over the years has become standard practice for the installation of all socket weld flanges (SW Flange).

Socket Weld Flanges are available in pressure from 150# and up and pipe schedule 40 to schedule 160. Specifying the pipe schedule ensures that ID of the SW Flange matches the ID of pipe for smooth fluid flow.

Trupply offers SW Flange in A105N, A105, SS316, SS304, A20, High Yield & Nickel Alloys. Email [email protected] for all your flange buying needs.

Socket Weld flanges were initially developed for use on small-size high pressure piping. Their static strength is equal to Slip On flanges, but their fatigue strength 50% greater than double-welded Slip On flanges.

The connection with the pipe is done with 1 fillet weld, at the outside of the flange. But before welding, a space must be created between flange or fitting and pipe.

ASME B31.1 1998 127.3 Preparation for Welding (E) Socket Weld Assembly says:

In assembly of the joint before welding, the pipe or tube shall be inserted into the socket to the maximum depth and then withdrawn approximately 1/16″ (1.6 mm) away from contact between the end of the pipe and the shoulder of the socket.

The purpose for the bottoming clearance in a Socket Weld is usually to reduce the residual stress at the root of the weld that could occur during solidification of the weld metal. The image shows you the X measure for the expansion gap.

The disadvantage of this flange is right the gap, that must be made. By corrosive products, and mainly in stainless steel pipe systems, the crack between pipe and flange can give corrosion problems. In some processes this flange is also not allowed. I am not an expert in this matter, but on the internet, you will find a lot of information about forms of corrosion.

Also for this flange counts, that principle always firstly a pipe must be welded and then just a fitting.

Please contact us today for more information about our wide range of Piping Products and Fabricated Piping Products. If you don’t see the type of gasket you need here? Not to worry! Benchmark has local stock on hundreds of types of Piping Products not listed and are updating our online inventory daily. What’s more if we don’t have it we will find someone who does and deliver to your site as fast as same day if possible.