Neoprene Synthetic Elastomeric Bearing Pads

Neoprene Synthetic Elastomeric Bearing Pads can be used for bridges, viaducts, buildings, storage tanks, sealing elements, isolation, etc.

Benchmark can cut our Elastomeric Bearing Pads to any shape you require including rectangle, circles, squares etc. We can also cut holes and slots into the Elastomeric Bearing Pads as required or we can bond the bearing pad materials to carbon steel or stainless steel.

Properties of Neoprene Synthetic Elastomeric Bearing Pads:

| Material Properties: | ASTM Standard Test: | Test Results (Standard) |

|---|---|---|

| Hardness, Shore A | D2240 | 55 +- 5 |

| Tensile Strength, MPa | D412 | Minimum 17.0 |

| Ultimate Elongation, % | D412 | Minimum 400 |

| Specified Test Temperature | D573 | 70h at 70 degrees C |

| Change in Hardness, Shore A | D573 | Maximum + 10 |

| Change in Tensile Strength, % | D573 | Maximum -25 |

| Change in Ultimate Elongation, % | D573 | Maximum - 25 |

| Specified Test Temperature | D395 | 22 h at 70 Degrees C |

| Residual Compression, % | D395 | Maximum 25 |

| Mounting Procedure A | D1149 | 22 pphm, 48 h |

| 20% Strain, 40 +- 2 Degrees C | D1149 | No cracks |

| Bond Between Steel and Elastomer Laminate, N,mm | D429 | Minimum 7.0 |

| Brittleness at -10 degrees C | D746 | No Failure |

| Low Temperature Crystallization Increase in Hardness, Shore A | D2240 | 168 h at -25 Degrees C Maximum + 15" |

Data is from CAN / CSA-S6-06

Other grades and durometers are available to meet AASHTO, AREMA or any other standards required.

Benchmark accepts no responsibility for individual results obtained. Everyone is strongly recommended to verify data and obtain their own independent test results. This data is subject to change without notice.

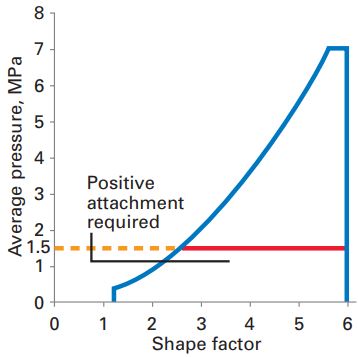

Elastomeric Bearing Shape Factor Considerations:

Elastomeric Bearing Shape Factor (S):

SF = Loaded Area / Bulge Area

SLS = Serviceability Limit State

ULS = Ultimate Limit State

Maximum pressure under permanent load = 4.5 MPa (SLS), 7.0 MPa (ULS)

Maximum pressure under total load = 7.0 MPA (SLS), 10.0 MPa (ULS)

Elastomeric Bearing Shape Factor Considerations:

Maximum shear deformation of a plain elastomeric bearing pad is limited to 50% of the total pad thickness.