There are many cases in which UHMW is specified for installations where its ultimate abrasion and impact resistance are not necessary. In many cases, the customer’s only alternative was to use standard HDPE, which lacks the durability of UHMW in most applications.

VHMW (Very High Molecular Weight polyethylene), is a unique product designed to be a perfect complement to UHMW and to bridge the wide performance gap between HDPE and UHMW. When used properly, VHMW allows distributors and manufacturers to reduce costs while suffering no performance loss. Naturally, good design practices dictate that new applications should always be tested before full-scale operations begin.

Polyethylene (PE) is one of the largest volume thermoplastics used today and is available in a wide range of grades and formulations (commonly, LDPE, HDPE). The various formulations impart a wide range of properties to the polymer making it appropriate for countless applications. Generally speaking, PE is tough, chemical resistant and offers good electrical properties with a low coefficient of friction and moisture absorption. They are relatively light weight and easy to fabricate.

Prolonged outdoor exposure won’t discolor or degrade these VHMW sheets. They have excellent impact resistance and are often used as chutes, liners, and gaskets.

Very high molecular weight polyethylene (VHMW-PE) is an excellent choice as an interim material, fitting nicely in it’s properties between HDPE and UHMW. VHMW is a good choice when increased durability, abrasion resistance and performance is required vs. HDPE, but the properties of UHMW are more than the application requires.

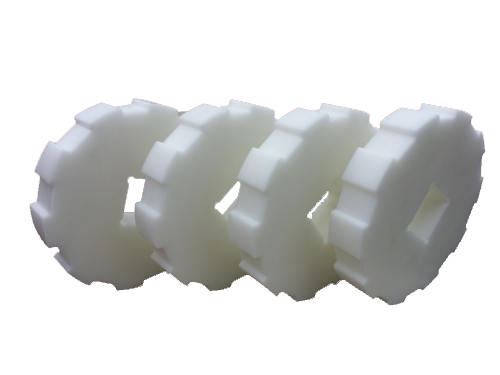

Ultra High Molecular Weight polyethylene (UHMW-PE) offers a combination of excellent properties – outstanding abrasion resistance, superior impact resistance, non-sticking and self-lubricating properties and excellent mechanical properties, even in cryogenic conditions.

HDPE Applications

VHMW-PE Applications

UHMW-PE Applications