PTFE Slide Bearing systems offer a low profile solution for allowing relative movement between structural elements.

Thermal cycles, seismic activity, variable loading conditions, and long term material changes are some of the conditions that must be accommodated by the structural system. Typical applications are at floor and roof framing connections along expansion joint lines in large structures, truss base plates, pipe supports, heat exchangers, and other process equipment.

The upper element is sized to provide full coverage of the lower element throughout the range of allowed movement. This ensures that full contact is maintained on the lower element and allows the upper element to provide full coverage for the lower element. Following this best practice approach for element sizing will maximize product life cycle by eliminating partial loading situations and minimizing the risk that foreign material will enter the sliding interface.

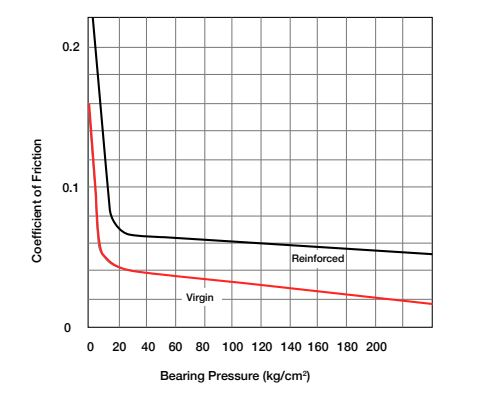

The coefficient of friction of PTFE materials is dependent on many variables, including pressure, sliding velocity and temperature. A design coefficient of friction of 0.1 for unified PTFE or 0.12 for reinforced PTFE will give a significant margin of safety when all operating conditions cannot accurately be predicted; but the figures in practice will normally be considerably less.

There are many applications in industry where relative movement between two surfaces must be accommodated.

These applications call for high load capacity at low speed, meaning self lubricating PTFE is an ideal material to be employed. Benchmark has amassed a great deal of experience in designing and supplying custom made expansion bearings to address this issue.

PTFE structural expansion bearings are custom designed to accommodate expansion, contraction and other reciprocating motions of any structure that moves as a result of thermal, seismic or differential forces.

Benchmark offers a custom production, based on many years’ experience of the manufacturing of PTFE Slide Expansion Bearings. Low friction slide plates with a coefficient of friction less than 0.1 are

available.

PTFE Slide Bearings are designed specifically for the loads and movements required. The standard slide plate assemblies FTFE to Stainless Steel and PTFE to PTFE are designed to operate efficiently at the loadings shown.

It is important to note that the maximum service temperature relates to the sliding face of the bearing assembly. As a rule of thumb, under normal conditions the temperature falls by 200°C for every 100mm from the heat source (in ambient air) for example, a typical horizontal vessel operating at 500°C will have a bottom-of-saddle temperature of about 150°C.

Where PTFE is used and the temperature of the bearing face is likely to exceed 200˚C by conduction through the bearing components, a thermal barrier can be interposed between the heat source and the sliding unit. Thermal barriers are not usually needed

The following steps will provide an indication of the slide bearing requirements for a particular application:

Chemical bonding with epoxy is the recommended method for attaching the slide bearing material on its support, because the shear value of the epoxy adhesive is greater than that of the PTFE itself.

Bonded PTFE elements are not adversely affected by exposure to ultraviolet light, providing the minimum thickness requirement of 1.5mm is met. Site bonding of PTFE is not recommended as strictly controlled conditions of cleanliness, pressure and temperature are required to obtain a satisfactory bond between the PTFE and the substrate

The bearing components can be located to the installation by bolting, tack-welding, full welding or mortar embedment, and the appropriate type of bearing should be chosen according to the installation method. The PTFE should be adequately protected against weld spatter, paint spray, metal swarf etc., during installation.

Slide bearing units can be built with a variety of elastomer composite interlayers or backings to suit customers design parameters when acoustic or vibration damping is necessary. Elastomers may be used when simple angular or rotational movements are required.