Etched PTFE

PTFE is an amazing non-stick material, but what about when you need to glue it to the surface of another material ? In order to bond standard PTFE to another surface such as stainless steel, a process called “etching” is required. Typical applications would include the lining of chemical process tanks or other equipment used in caustic environments. When bonding is needed, sodium ammonia etching is usually the most economical answer. This process uses of a mixture of sodium and ammonia that is formulated to create a bondable surface both quickly and efficiently. Sodium/ammonia etching service complies with all applicable commercial, military & federal specifications for the surface treatment of all fluoropolymers including: PTFE, PFA, FEP, ETFE, PCTFE, PVDF, PVF, & ECTFE.

From microchips to full size rolls, fluoropolymers of any shape or complexity, including tape, sheet, tubing, molded shapes & machined parts of any configuration can be etched & bonded. This treatment can be accomplished on one or more surfaces, or selectively within close tolerances.

Made with Teflon® PTFE resins, these sheets and bars surpass most plastics when it comes to chemical resistance and performance in extreme temperatures. In addition to resisting most solvents, they are excellent electrical insulators. They’re easy to machine and have a naturally slippery surface that makes them a good choice for bearings, gears, and parts that slide and roll.

Sheets and bars with an etched texture have one side that is scuffed to readily accept adhesive; the other side is smooth and is made of FDA listed material.

Skived sheets and bars are more likely to curl than molded sheets and bars.

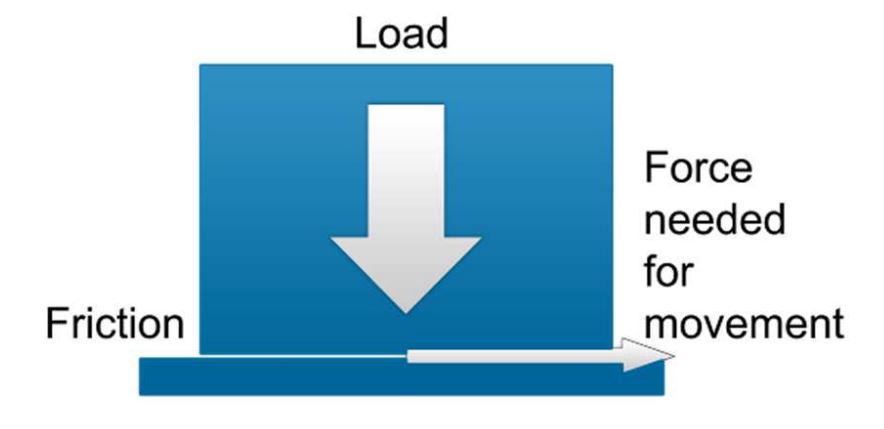

PTFE has the lowest friction coefficient of all materials. Benchmark PTFE Slide bearings have a sliding pad out of modified PTFE or an engineered plastic with PTFE supplement.

The friction coefficient will be at a minimum when the stress in the PTFE is at a maximum and the counter surface is mirror polished. By using special PTFE compounds the stress in the PTFE can be influenced in a positive way without reducing the maximum allowable load. Therefore Benchmark PTFE Slide Bearings have a very low friction coefficient.

Benchmark stocks and converts PTFE Sheets in a wide range of thicknesses up to 1″. Our thick gauge PTFE Sheets have excellent thermal and electrical insulation properties and a low coefficient of friction.

PTFE is inherently super slippery and extremely temperature/chemical resistant, making it a highly suitable material to be used in the toughest applications. Benchmarks custom converting capabilities enable us to produce cut strips, rectangles, or custom die cut parts.

Polytetrafluoroethylene (PTFE), generally referred to as Teflon® (a registered trademark of DuPont), is a synthetic, nontoxic, fluorocarbon-based polymer that is widely used in many applications. PTFE’s low coefficient of friction, excellent electrical properties, high chemical resistance, and stability in wide temperature ranges make it a choice material for electrical and thermal applications as well as bearing pads.

Virgin PTFE is made from pure PTFE resin with no added recycled material. Virgin PTFE is extremely chemical resistant, serves as an electrical insulator, and retains flexibility in low temperatures. Virgin PTFE is FDA approved and is often used in food and beverage, pharmaceutical, and cosmetic applications.

Benchmark stocks a wide range of thickness of skived PTFE sheets provide excellent precision and cleanliness for a wide range of critical applications, including vessel linings, gaskets, rings, pump interiors, dip tubes, washers, seals, spacers and chemical tanks. This is because PTFE sheets are chemically inert, have a large thermal range, and are resistant to corrosion.

Skived PTFE sheets and cut parts are available in a wide range of material variations and in continuous rolls or can be cut to your desired length. We offer standard or custom widths to reduce wastage and scrap.

Benchmark is a stocking PTFE sheet manufacturer with in-house cutting and tooling capabilities. We have tooling available to laminate, punch, or die cut all our skived PTFE sheet and film products. All our PTFE sheets can be furnished with or without surfaces etched for adhesive bonding.