Research has shown that thermal bridging can increase the whole-building conductive heat loss by more than 15%. The percentage is a function of the following variables: climate, building type, location and type of the thermal bridges. The magnitude and quantity of the thermal bridging is a large factor. Some interface details increase the U value of a wall by 45% or more, other transition details increase the U value by only 5%.

The purpose of thermal break materials and systems (thermal breaks) is to reduce the impact of thermal bridging by preventing conductive heat flow through the thermal envelope. Thermal breaks keep the heat in and push the dew point out. They break the bridge.

Research has shown that thermal bridging can increase the whole-building conductive heat loss by more than 15%. The percentage is a function of the following variables: climate, building type, location and type of the thermal bridges. The magnitude and quantity of the thermal bridging is a large factor. Some interface details increase the U value of a wall by 45% or more, other transition details increase the U value by only 5%.

STB-1 Structural Thermal Break

STB-1 Thermal Break Pads are often called Thermal Bridges, balcony isolators, structural thermal breaks, cantilever steelwork thermal bridging, cold bridge isolation, thermal partitions, steelwork thermal break, thermal bridging, cold bridging pads, cold bridging solutions. All of these solutions use Thermal Insulation Material to prevent thermal bridging.

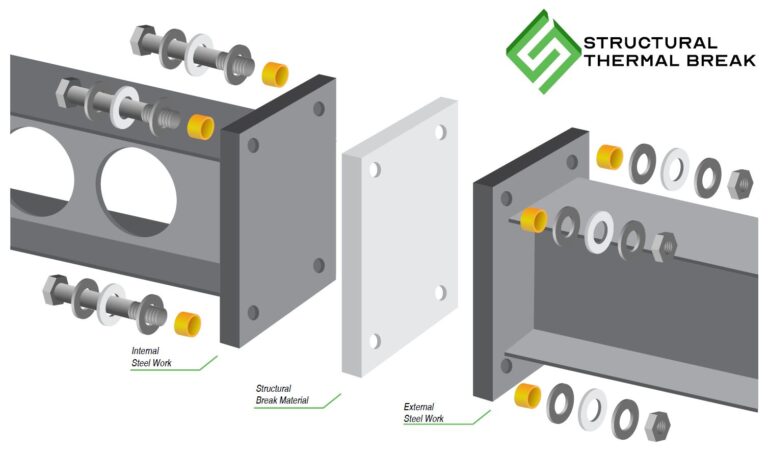

A complete STB-1 Structural Thermal Break system include a thermal break pad, 2 thermal break washers, 2 thermal break bushings and 4 USS Grade 8 steel washers.

With more code changes coming into play each year to protect the future of the construction industry, STB-1 Structural Thermal Break can be used in renovation projects to rectify a number of poorly isolated connections within existing buildings, as well as structures under construction to make them as efficient as possible. To achieve this and work towards making any building as efficient as possible, these solutions need to be considered within the earliest stages of a construction project, which is why it’s imperative for architects to understand the importance of these products and how they can help a structure meet certain efficiency criteria.

When using STB-1 Structural Thermal Break pads in a parapet roof location, the U value of the roof assembly will be improved, and the potential chances of condensation problems occurring will be prevented at the structural connection.

STB-1 Structural Thermal Break is a structural high performance thermal break material which delivers thermal insulation between interior and exterior steelwork, and / or concrete, to prevent thermal bridging.

STB-1 Structural Thermal Break can help work towards improving building envelope performance, dramatically reducing heat loss and preventing surface condensation from forming inside the building that can be caused by cold transfer meeting warm air.

The thermal conductivity of a material is a function of its conductance which helps determine the rate at which heat flows through that material. Heat flow is also dependent on area and temperature.

Conductance is a function of thickness, so to be effective at reducing heat flow through a bolted, steel connection, the thickness of the thermal break is important.

STB-1 Structural Thermal Break material is available in several thicknesses to accommodate a wide range of connection details. In any connection design, the goal is to use the appropriate thickness/area which helps meet energy code requirements for the wall or roof assembly.

STB-1 Structural Thermal Break concrete connections address high risk structural steel connections and the thermal loss they create.

| Tensile Strength | PSI (MPa) | ASTM D638 | 11,000 (75.8) |

|---|---|---|---|

| Flexural Strength | PSI (MPa) | ASTM D790 | 25,000 (172.4) |

| Compressive Strength | PSI (MPa) | ASTM D695 | 48,000 (330.9) |

| Compressive Modulus - 1/2" (12.7 mm) thick | PSI (MPa) | ASTM D695 | 291,194 (2,007.7) |

| Compressive Modulus - 1" (25.4 mm) thick | PSI (MPa) | ASTM D695 | 519,531 (3,582.0) |

| Shear Strength | PSI (MPa) | ASTM D732 | 15,000 (103.4) |

| Operating Temperature Range | F (C) | - | -20 to +250 (-29 to + 121) |

| Thickness | Inch (MM) | - | 1/4, 1/2, 3/4, 1. 2 (6.4, 12.7, 19.1, 25.4, 50.8) |

| Oxygen Index | % O2 | ASTM D2863 | 21.8 |

|---|

| Coefficient of Thermal Expansion | in/in/Cx10-5 | ASTM D696 | 2.2 |

|---|---|---|---|

| Thermal Conductivity | BTU/Hr/ft2/in/F | ASTM C177 | 1.8 |

| Density | lb/ft3 (Kg/M3) | 115 (1842) | |

| **Reference: Thermal Conductivity of Steel | BTU/Hr/ft2/in/F (W/m*K) | 374.5 (54.0) |

| Barcol Hardness | Barcol | Scale | 48 |

|---|---|---|---|

| Water Absorption, % | D-229 | % | 0.35 |

| UL Flammability | UL94 | Class | HB |

| Flame Resistance, Seconds Ignition Time Burning Time |

D-229 D-229 |

Seconds Seconds |

103 211 |

| Modulus of Elasticity in Flexure | PSI D-790 | PSI | 1.6 x 106 |

|---|---|---|---|

| Bond Strength, 1/2" Thickness, PSI | D-229 | PSI | 1,200 |

| Impact Strength, Izod Edgewise | D-256 | Ft lbs / In. Notch | 8.5 |

| Dielectric Strength, Short Time in Oil 1/16", VPM | D-149 | VPM | 500 |

|---|---|---|---|

| Arc Resistance, Seconds | D-495 | Seconds | 150 |

| Dielectric Constant @60HZ | D-150 | 4.8 | |

| Dissipation Factor @ 60HZ | D-150 | 0.02 |

Structural Thermal Break (STB-1) reduces heat loss at balcony, canopy, shelf angle, roof post and other structural connections.

Structural Thermal Break (STB-1) is a thermoset, reinforced composite. It can transfer loading conditions up to 48,000 psi and has very good fire properties. The material has been designed to form a char when exposed to flame and reduce the amount of oxygen available to a fire.

Depending on the material being cut or bonded Benchmark will use CNC Router Machines, Waterjet Cutters, CNC Laser, Hydraulic Presses and more. Since we keep many of these machines “in house” we are able to dramatically reduce our processing time compared to alternative products.