Depending upon the size and thickness, STB-1 Structural Thermal Break can ultimately withstand loads up to 12,000 psi. Normally, compression stresses are designed not to exceed 2,000 psi to extend service life and reduce permanent set.

One of the advantages of the reinforced, laminated design is the reduction of additional deflection due to creep under static load. Creep is limited to approximately 5% of the original pad thickness. When stresses are removed, the permanent set is also limited to approximately 5%.

STB-1 Structural Thermal Break pad / connection, or thermal insulation material (STB-1), is manufactured from a fiberglass-reinforced laminate composite. The properties of this material provide a thermally efficient, energy-saving product that prevents thermal bridging in structural connections. STB-1 Structural Thermal Break is a load bearing “thermal break” used between flanged steel connections. The primary benefit is that it maintains structural integrity while reducing heat loss.

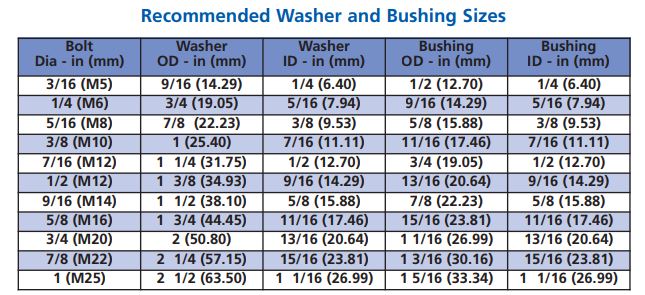

STB-1 Structural Thermal Break material is supplied in sheets or cut to size per customer drawings/specifications and is available in thicknesses of 1/4″, 1/2″ and 1″. It is also supplied as thermal break washers for the bolted connections between external and internal steelwork.

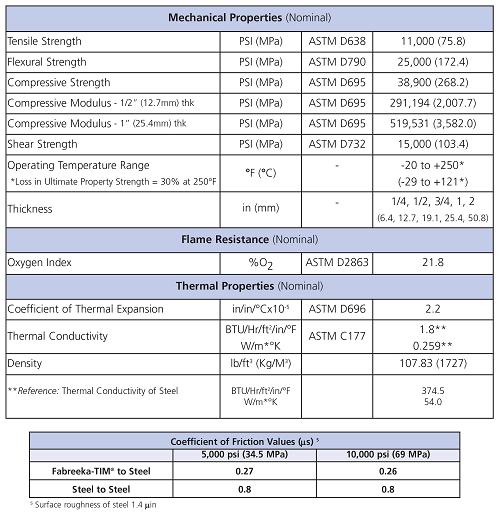

Please see our STB-1 Structural Thermal Break and design guide for mechanical and thermal properties.